The field of metabolic engineering has reached the point where microbes can be engineered for the production of an amazing array of chemicals. However, a hurdle to the economic viability of such fermentative processes is the need to produce the target molecule at a high concentration. Processes in which the target is dilute in the fermentation broth incur high downstream processing costs. This need to produce the target molecule at a high concentration is often harmful to the organism. Consider the fact that alcohol is used to sterilize surfaces, and yet we want our microbes to produce alcohols at a high concentration. This problem of product toxicity is not limited to alcohols, it is widespread in the microbial production of biorenewable fuels and chemicals.

Microbial inhibition is also problematic in the utilization of biomass-derived sugars. We aim to release sugars from biomass in a manner that is fast and cheap, but the resulting sugar solutions are “dirty” and contain compounds that are inhibitory to the microbial biocatalyst. This limits the amount of sugars that can be fed to the organism and, in turn, limits the product concentration. Adding processing steps to detoxify the sugars can incur an unacceptable increase in process cost. An alternative approach is to develop organisms that can tolerate these inhibitors.

Historically, evolution has been used to increase microbial robustness. Our long-term goal as engineers is to employ a rational, predictive approach for improving microbial tolerance. Thus, the main theme of the Jarboe research program has been understanding the mechanisms by which toxic molecules are harmful to microbes and then using a rational approach to modify the microbe for increased robustness. This approach started with my PhD work, with characterization of the inhibition of Escherichia coli by two compounds produced by the mammalian immune system, with the goal of understanding pathogenesis. My postdoctoral research included characterization of the inhibition of ethanol-producing E. coli by furfural, an inhibitory compound that is abundant in biomass-derived sugars.

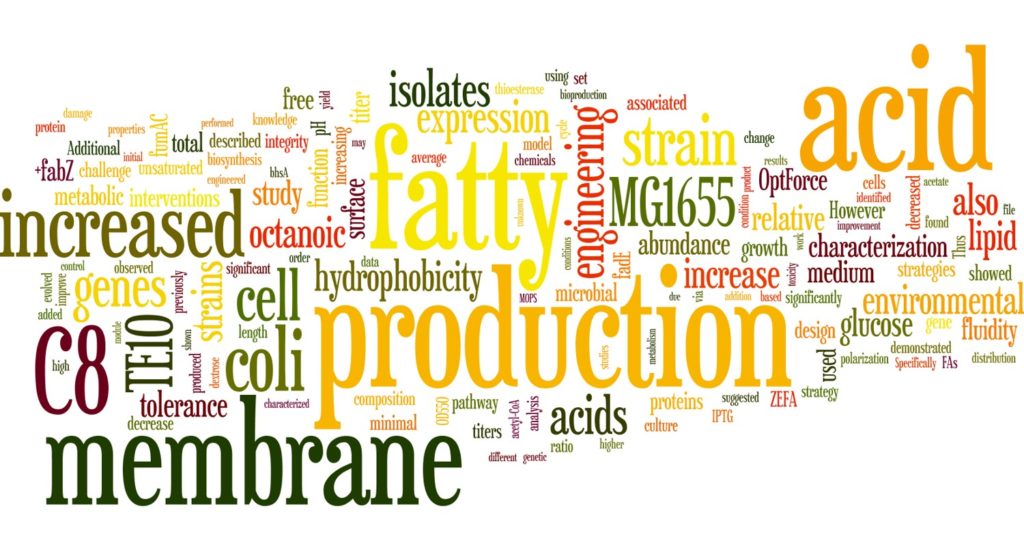

At Iowa State University, the Jarboe group has characterized inhibition of E. coli and Saccharomyces cerevisiae by carboxylic acids, as funded by the NSF Center for Biorenewable Chemicals Engineering Research Center (CBiRC). A variety of our publications have rigorously and quantitatively demonstrated that (a) membrane damage is the main mode of carboxylic acid toxicity to E. coli and S. cerevisiae; and (b) that changes in the membrane composition are associated with increased carboxylic acid tolerance and production. My group has also demonstrated that membrane damage is a challenge during production of other important biorenewable fuels and chemicals, such as styrene.

Rational engineering of membrane composition

Given the findings that membrane damage is a common theme during the production of biorenewable fuels and chemicals, the microbial membrane is an obvious target for rational modification efforts. The analogy that we like to use here is of a standard reaction vessel. If, during the course of the chemical reaction, you observe that the reaction vessel is vulnerable to corrosion by the vessel contents, you would modify your process so that a vessel with a different composition is used. Here we propose to take the same approach with the microbial cell membrane – if the membrane is vulnerable to damage by the metabolic product, then the composition of the membrane should be altered in order to increase resistance to this damage.

Previous efforts by my own group and others have focused on changing the distribution of naturally-occurring membrane components. Specifically, efforts have focuses on changing the distribution of saturated lipids and unsaturated lipids. These efforts were effective in increasing tolerance of the inhibitory compound, but there have been no successful reports of this sort of membrane engineering approach actually improving production.

The Jarboe group has shown that modification of E. coli to produce a non-native membrane component that improves the structural integrity of the membrane. Specifically, we introduced an enzyme that isomerizes some of the existing cis lipids to the trans form, a strategy that is used by Pseudomonas bacteria to improve tolerance to membrane-damaging compounds. This modification decreased the membrane fluidity and improved fatty acid production and styrene production. Tolerance to other important biorenewable products, such as the second-generation biofuel n-butanol, and factors important to the cost-effective production of biorenewable fuels and chemicals, such as tolerance to high temperature and low pH, were also significantly increased.

Membrane engineering for increased microbial robustness is an ongoing area of research in the Jarboe lab.